When it comes to precision manufacturing, CNC (Computer Numerical Control) services have become an industry standard, revolutionizing the way materials are shaped and refined. At Radmot, we pride ourselves on offering some of the best CNC services available in the market today, specializing in turning and milling operations. Whether you’re working with metals like aluminium, steel, copper, or brass, or require precision work on plastics and other materials, our team delivers exceptional quality at a competitive price. Our approach to CNC machining ensures that each piece meets exact specifications and stands up to the most demanding applications.

Choosing the right CNC service provider is crucial for any project that requires precision and reliability. At Radmot, we understand that businesses rely on us for not only quality machining but also efficiency and affordability. We’ve worked hard to perfect the balance of high-quality service and cost-effectiveness, especially when it comes to bulk orders. We recommend that customers with production needs of at least 100 units per series and 1,000 units annually will find the best value with our services. This combination of quality and pricing allows businesses to scale their operations without sacrificing precision or breaking their budgets.

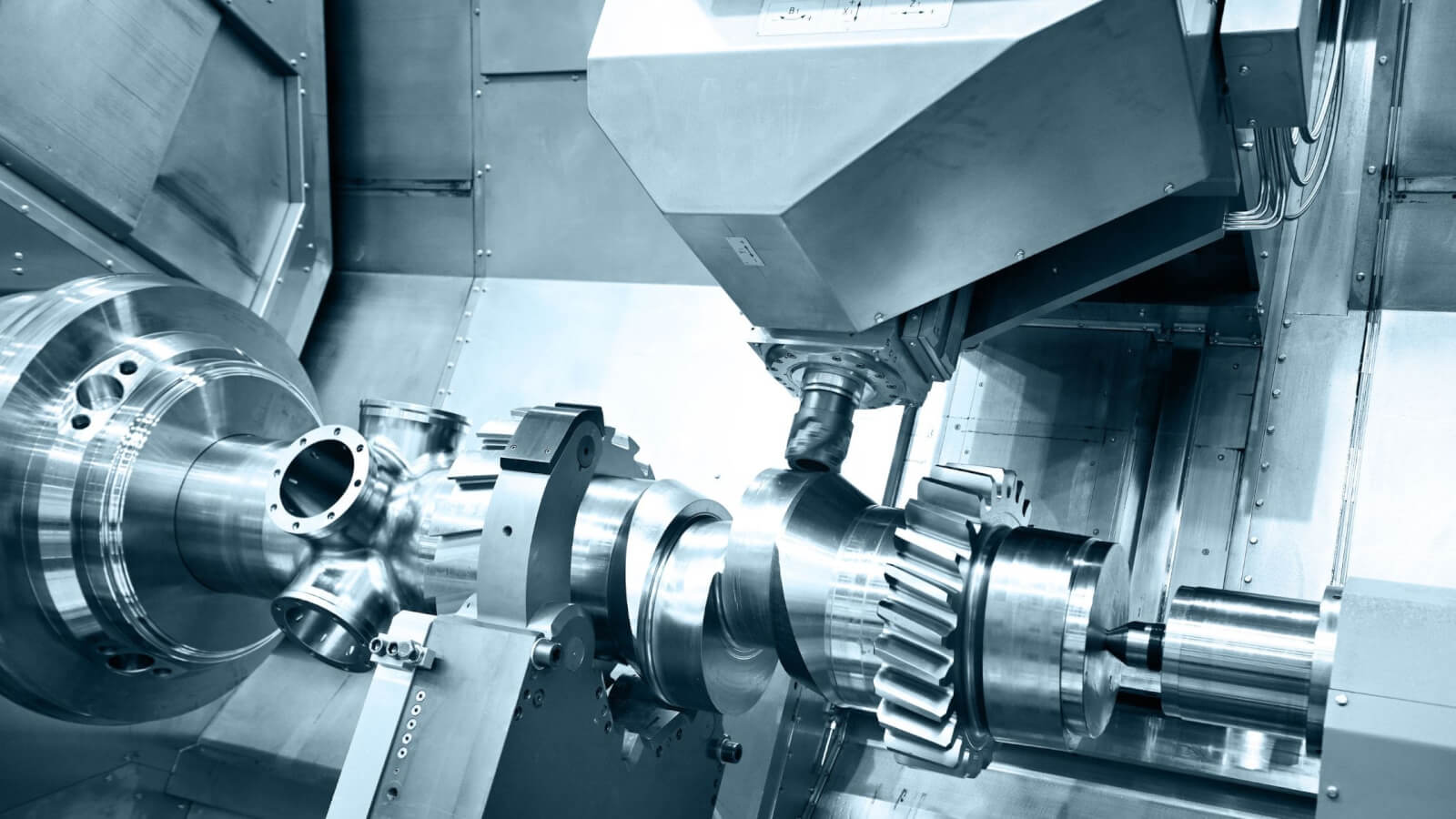

Precision CNC Turning and Milling: The Core of Our Service

CNC turning and milling are at the heart of modern manufacturing. These services offer precise control over the machining of materials, making it possible to produce complex parts that meet exact design specifications. At Radmot, our CNC turning service uses advanced lathes to rotate materials and shape them with cutting tools. This process is ideal for creating cylindrical components, such as shafts, bushings, and threaded rods. Whether you’re looking for simple or intricate designs, CNC turning ensures the highest level of accuracy, repeatability, and smooth surface finishes.

On the other hand, CNC milling is the go-to service when you need precise cutting and shaping across multiple axes. Using high-tech milling machines, we can manipulate materials in ways that produce a wide variety of shapes and designs, from simple slots and holes to intricate geometries. Our skilled operators and state-of-the-art equipment make CNC milling one of the most versatile services we offer, capable of working with metals like steel and copper, as well as plastics and other specialized materials.

Both CNC turning and milling allow us to deliver products that meet tight tolerances and maintain consistent quality, even with large-scale production runs. Whether you’re producing prototypes or ready-to-use parts, you can trust Radmot to provide the expertise and precision that your projects demand.

Materials We Work With: Metals and Beyond

The variety of materials we work with is another factor that sets Radmot apart from other CNC service providers. We have extensive experience machining a wide range of metals, including aluminium, steel, copper, and brass, each offering distinct properties that can be used to the advantage of your specific application. Aluminium, for instance, is lightweight, corrosion-resistant, and easy to machine, making it perfect for industries such as automotive and aerospace. Steel, on the other hand, offers strength and durability, ideal for structural components and heavy-duty applications.

Copper and brass, known for their excellent conductivity and malleability, are often used in electrical components, fittings, and decorative pieces. However, our capabilities go beyond metals. We also machine various plastics, such as acrylic, nylon, and polycarbonate. Plastics are highly versatile, providing cost-effective solutions for projects where weight reduction or specific chemical resistance is required.

By offering such a diverse selection of materials, Radmot can accommodate a wide range of industries and project types. Our flexibility ensures that whatever your material needs, we can deliver the right solution, whether it’s a small, intricate part or a large-scale production run.

The Ideal Balance of Quality and Price

One of the primary concerns for any business is balancing quality with cost, especially when it comes to manufacturing. At Radmot, we’ve tailored our services to provide an optimal ratio of service quality to price. Our CNC services are best suited for production volumes starting from 100 units per series, with an annual production requirement of 1,000 units. This model ensures that our customers can benefit from cost savings achieved through economies of scale, without compromising the precision and attention to detail that defines our work.

In addition to our competitive pricing structure, we place a strong emphasis on quality control. Every piece that comes through our CNC machines is thoroughly inspected to ensure it meets the exact specifications of the project. This attention to detail guarantees that our customers receive not only a fair price but also products that will perform reliably in their intended applications.

For businesses looking to outsource their CNC turning and milling needs, Radmot offers an unbeatable combination of precision, speed, and affordability. Our team works closely with customers to understand their specific needs and provides tailored solutions that meet both technical and financial requirements.

Why Choose Radmot for Your CNC Services?

Choosing Radmot for your CNC services means partnering with a team that is committed to your success. We understand the importance of precision in manufacturing and work diligently to ensure that every part we produce meets the highest industry standards. Whether you need simple parts or complex assemblies, our advanced CNC machinery and experienced operators are up to the task.

We also value customer relationships and strive to offer more than just a service—we aim to be a trusted partner in your production process. From the initial consultation to the final delivery, our team is available to provide advice, updates, and support throughout every step of your project.

By focusing on CNC turning and milling, as well as working with a wide range of materials, we’re able to provide a comprehensive manufacturing solution. Our dedication to maintaining the highest quality standards while offering competitive pricing makes Radmot the ideal choice for businesses looking to outsource their CNC needs.

In conclusion, whether you are a small business just starting or a large company with high-volume production needs, Radmot has the expertise, equipment, and commitment to quality that will help you achieve your goals. Our CNC services are designed to deliver precision parts quickly, affordably, and to your exact specifications. Visit our website Radmot to learn more about how we can support your next project with our top-tier CNC turning and milling services.